― Increases in production levels comparable to output of a new oil project

Increases in crude oil production from ExxonMobil Guyana’s optimization efforts offshore Guyana are so substantial that they are comparable to adding an entire new oil development project. These increases, achieved through debottlenecking, have boosted output by 103,000 barrels per day (b/d) across the company’s three projects.

The first of ExxonMobil’s projects, Liza-1, began production in December 2019 with an initial target of 120,000 b/d. Thanks to optimization work, Liza-1 has managed to sustain production of approximately 160,000 b/d, an increase of 40,000 b/d. Similarly, Liza-2, which began production in February 2022, targeting 220,000 b/d, has been optimized to sustain producing up to 252,000 b/d, adding 32,000 b/d. Both Liza field projects demonstrated the capability to maintain optimized production levels for a month, averaging these new levels in February 2024.

Meanwhile, the Payara project, which started in November 2023 with a target of 220,000 b/d, has demonstrated optimized production of 251,000 b/d, an increase of 31,000 b/d. This project has benefited from learning from the first two developments. This approach has allowed ExxonMobil to optimize Payara in just eight months since First Oil, compared to Liza-2, which took 14 months.

ExxonMobil had also said it would undertake further optimization measures at Liza-2 during a shutdown period in June, gains which the company expects to see in new production data. Therefore, these optimizations will increase total production by 103,000 b/d, equivalent to the initial production target of a completely new project minus the billions in investment expenses.

Exxon and its partners spent USD19 billion to develop the first three projects with an initial target output from the trio of 560,000 b/d. That amounts to almost 30,000 b/d in new production for every USD1 billion spent. On this basis, the 103,000 b/d gains from production optimization would equate to a development spend of USD3.5 billion. These cost savings, so to speak, validate ExxonMobil’s optimization strategy.

The economic impact of this optimization is significant. Increased production means a higher crude share for each partner, resulting in additional revenue for ExxonMobil, Hess Corporation, CNOOC Petroleum Guyana Limited, and the Government of Guyana. Furthermore, Guyana benefits from increased royalties, as the country receives 2% royalty from all crude produced and sold. The increased production boosts these revenues in proportion to the additional output.

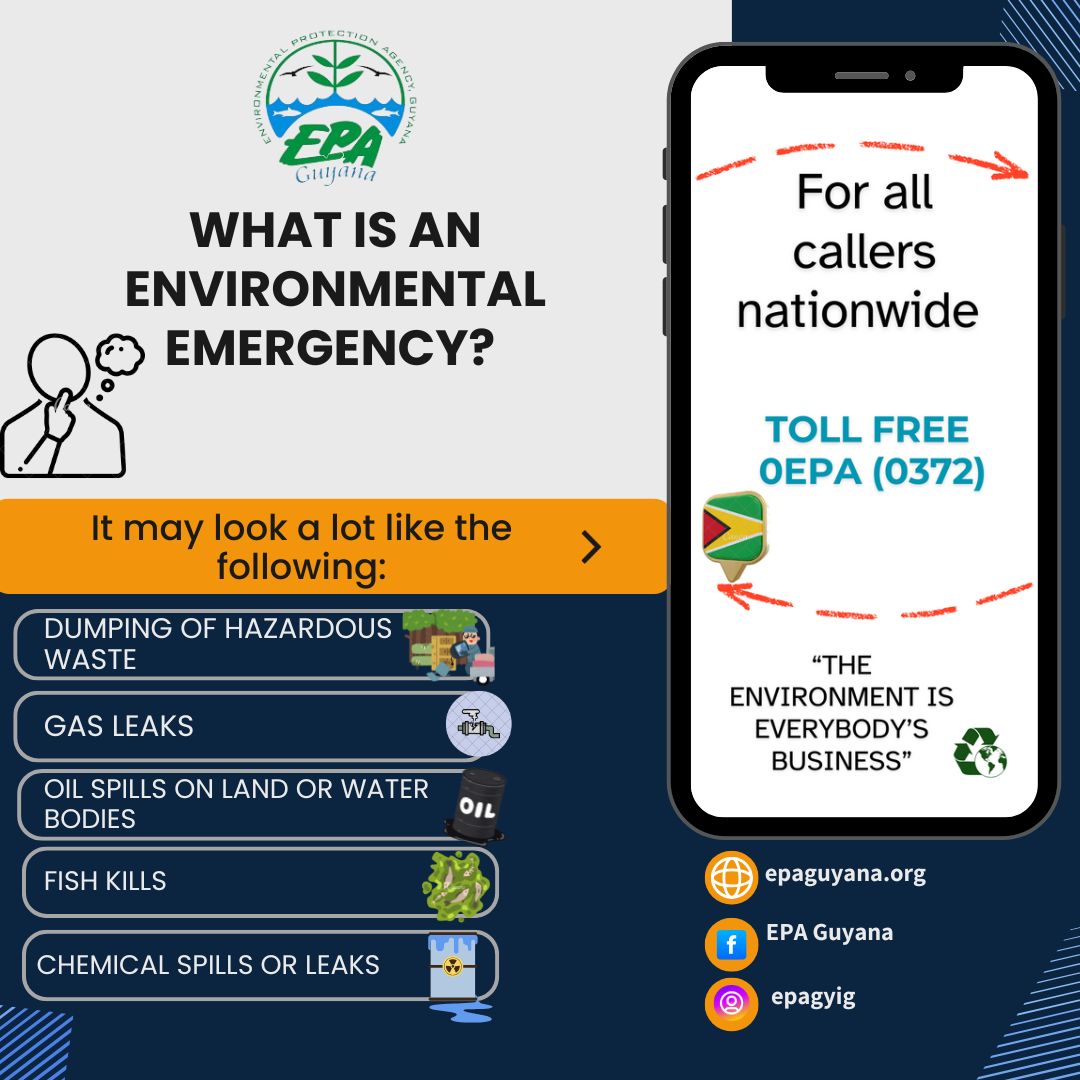

The regulatory process around production optimization is also a critical component of this success. The Government of Guyana, through the Environmental Protection Agency (EPA), said it ensures that the pursuit of optimization is safe and environmentally sound. When a company like ExxonMobil embarks on a project, it must submit a project summary to the EPA, which typically requires an environmental impact assessment (EIA).

The EIA assesses the potential environmental impact of production at the initial target level and higher optimized levels. For example, Liza-2’s EIA studied the impact of production up to 300,000 b/d, beyond its initial target of 220,000 b/d. Once the EPA approves the project, it has already considered the environmental impact of production above the initial target, giving ExxonMobil flexibility to increase output safely.

Additionally, when ExxonMobil seeks to optimize production even more, it notifies the government, and the EPA reviews the optimization plans to ensure they are safe. According to Minister of Natural Resources Vickram Bharrat, the government closely monitors these measures to ensure that the integrity of the infrastructure is not compromised. This monitoring ensures that the company conducts any optimization responsibly, safeguarding both reservoir performance and the facilities used to extract the oil.

With upcoming projects like Yellowtail, Uaru, and Whiptail expected to start in the next few years, the optimization strategy can maximize their value. Hess officials have said optimizing each project could increase production by 10%. Given that each new project set to come on stream initially targets production of 250,000 b/d, their combined gains from optimization could total 75,000 b/d.